Tomato Vinegar Experiment (3 Ways)

The tomatoes are coming off the vine in basketfuls every other day. I have more tomato plants this year than any year previously, and while I could absolutely eat caprese salad every day for a week, there are still too many to keep up with.

For some reason I got this idea stuck in my brain for tomato vinegar. I’ve been thinking and talking about it for a week now. I even bought a refractometer to test the °Brix of the various types of tomatoes I have. The results, however, are not promising.

To make vinegar, you must first make alcohol. You can absolutely make alcohol with tomatoes—it is a fruit that contains natural sugars. Here are the °Brix measurements of my tomatoes:

- Cherokee Purple (beefsteak): 6 °Brix

- Cherry Ember (cherry): 6.5 °Brix

- Honey Drop (cherry): 7.5 °Brix

Brix measures the amount of sugar in a solution, which gives you a rough idea of how much alcohol could be produced. The amount of alcohol with these tomatoes would be quite low, between 2-4%, if fermented dry. I’d be shooting for 6-8% at least to be on the safe side for stable homemade vinegar.

And so, 3 possibile paths stretch out before me.

- Add alcohol directly to tomato juice and then add raw vinegar

- Add sugar, ferment with yeast to develop alcohol, then add raw vinegar

- Add koji, incubate to develop sugars, ferment with yeast, then add raw vinegar

Yes, each method requires an additional step, but are the additional steps worth the hassle?

Were going to find out.

Day 1: 2021-08-07

I caved and bought an attachment for my stand mixer to handle separating the tomato juice & pulp from the skin and seeds.

- 3.5L tomato juice/pulp, ≈6°Brix

I’m going to start the most straightforward batch today by adding alcohol directly.

Tomato Vinegar #1: Soju

- 1.125L tomato juice

- 375mL Jinro 24 soju (1 bottle)

Jinro 24 is the strongest soju I can find locally at 24% ABV. Combining the quantities above, I should have a 6% ABV solution. Because I was curious, I measured the °Brix at 7.

The weight is 1460g. I’m adding 20% raw vinegar as an inoculant, which comes out to 292g. This just barely fits in the 1/2 gallon jar I’m using for this experiment.

Im roughly following the Noma Guide to Fermentation on vinegar for an accelerated process, which requires constant aeration. The microbes responsible for converting alcohol into acetic acid are aerobic, meaning they need oxygen, so pumping air in speeds up the process considerably. I’ve got a cheap little aquarium pump with an air stone which I’ve dropped in, then covered the whole jar with muslin cloth and a rubber band.

This should take approximately 10-14 days, as opposed to a month or more.

While that goes, I’m testing 2 other methods that require additional fermentation steps.

Tomato Vinegar #2: Sugar

Vinegar #2 will use an addition of sugar and yeast to ferment into alcohol before adding the vinegar starter.

- 1L + 220g tomato juice

- 180g sugar

- °Brix: 18.5

The additional tomato juice and amount of sugar will be explained in the next section, because they were directly influenced by the makeup of #3.

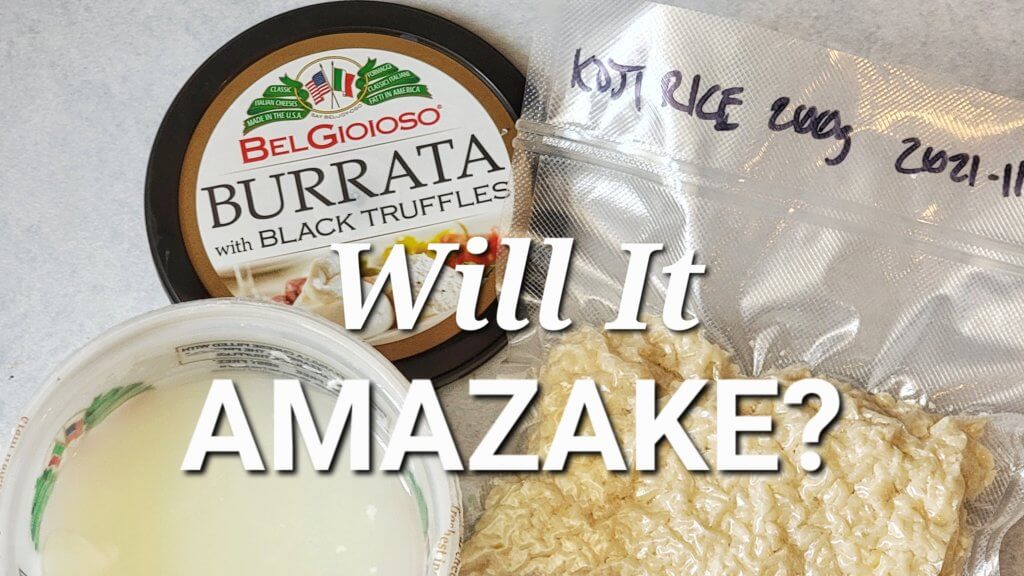

Tomato Vinegar #3: Koji

Vinegar #3 will use koji rice that must be incubated to convert the starches into sugars to make a “tomato amazake” which will then have yeast pitched to ferment the alcohol, after which the vinegar starter can be added. This was the most involved process I could think of.

- 1L tomato juice

- 400g koji rice

- °Brix: 12.5 (fuzzy reading)

According to Alfred Frances of Emmer & Rye during a session at Kojicon, roughly 45% of koji rice will convert to sugars. I have 400g of koji rice on hand, 45% of which is about 180g, which I added as pure sugar in #2. I added additional tomato juice as well in #2 to account for the additional mass of the koji rice not converting to sugars.

Water Bath: #2 & #3

Both #2 & #3 are going into a 140°F/60°C water bath for 14 hours. #1 needs this to rapidly convert the rice starches to sugars, and #2 is coming along for the ride because the yeast I have is liquid and must be used all at once, and I figure a pasteurization step won’t hurt before pitching the yeast.

Day 2: 2021-08-08

After 24 hours in the water bath, I took °Brix measurements again.

- #2: 18.5

- #3: 22.5

I was hoping these would be closer, not that they’re super far apart, but I now realize that I need to adjust Alfred’s equation when using glutinous rice as I do for most of my koji.

According to the Noma Guide to Fermentation, the °Brix need to drop by 3.5 to achieve 6% ABV:

- #2: 18.5 to 15

- #3: 22.5 to 19

I’m using White Labs Pure Pitch Belgian Ale yeast (WLP550). I pitched half the packet into each. I then realized that I did not have lids for these half gallon jars compatible with airlocks and I didn’t want to drill any holes, so I rigged up these crude airlocks using plastic bags and rubber bands.

I put these into a tray on top of a seed mat attached to a temperature controller set to 68°F.

I meant to check these every day, but…

Day 8: 2021-08-14

Oops. After no change in the °Brix readings for a few days I got busy and forgot to check for a 4 day timespan, during which the measurements would definitely have been changing. The delta I was shooting for was 3.5, my reading after a week of fermentation:

- #2: 7 °Brix (supposed to be 15)

- #3: 8 °Brix (supposed to be 19)

So yea. Completely and utterly overshot the fermentation time. I could have been more careful about calculating the amount of sugar needed to get 5-6% ABV, but my plan had been to halt the fermentation in another water bath. It is interesting though that the °Brix measurement is now pretty much on par for all 3 batches.

I pasteurized #2 & #3 at 140°F for 4 hours.

Day 9: 2021-08-15

Before adding the raw vinegar starter I put both through my cider press to get rid of most of the sediment. I then added 20% by weight in raw vinegar.

#2:

- 1060g fiktered tomato hooch

- 212g raw apple cider vinegar

#3:

- 933g koji tomato hooch

- 186g raw apple cider vinegar

These will now join #1 in the aeration process.

Day 23: 2021-08-29

Both #2 and #3 have now been aerating for 14 days. Batch #1 has been going this whole time, so 23 days. Something particularly interesting is that they all seem to be evaporating at different speeds, particularly 2 & 3.

The koji batch (3) has decreased by about 1cm, while the sugar fermented batch (2) is down maybe 0.5cm. By contrast, the soju batch (1) has only decreased about 1cm during a total of 3 weeks, a full week more than the other two. You can also see that the koji batch is leaving a dark, sticky residue on the cloth covering.

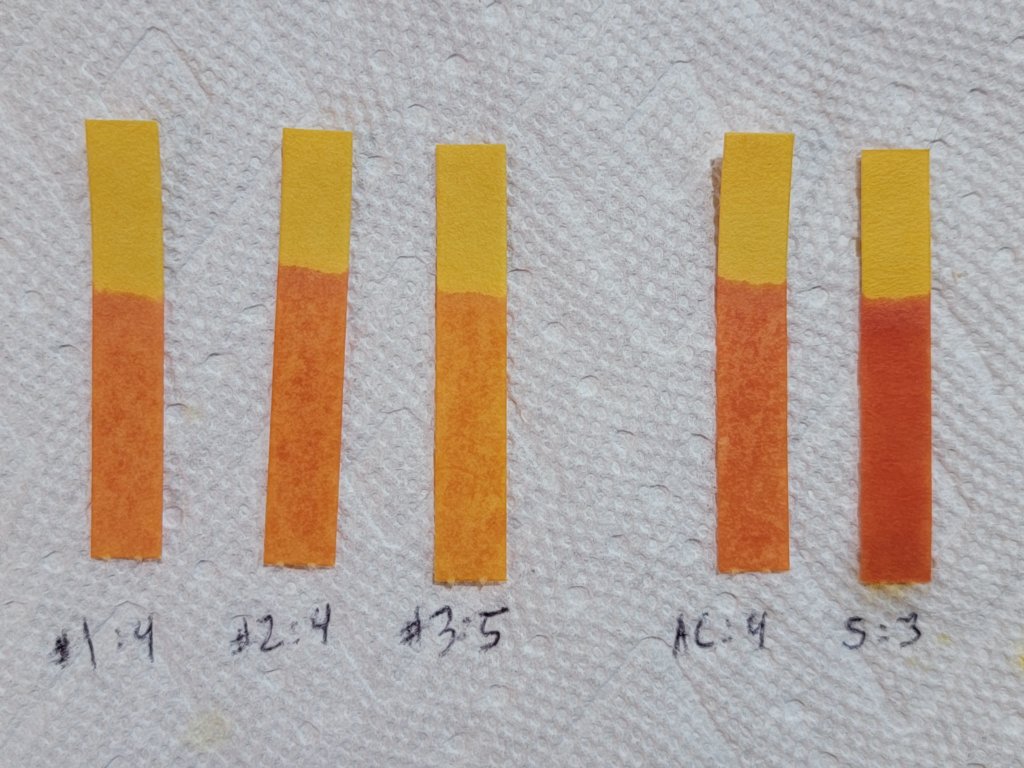

But what I really want to know is: was I successful in making vinegar? I took some pH readings to find out. For comparison, I took a reading of the raw vinegar from the store that I used as a starter, and also measured a batch of apple cider vinegar I’ve been making alongside these.

The “S” refers to the store bought, and “AC” is the apple cider vinegar test. While these test strips aren’t particularly precise, they do give me enough information to know whether the pH is generally low enough for stuff I make at home. I have a digital pH tester on my whishlist but haven’t been able to justify the cost yet (particularly of the kind that works for both solid and liquid foods).

I have to say, I’m not thrilled with these results. I was promised vinegar within 2 weeks but the pH is just barely in the range I’d normally consider shelf-stable (and #3 is not). However, I can tell that it did work—they taste like vinegar, just not quite so strong as the store bought stuff. One hypothesis I have is that the temperature in my basement has been just a bit too cool for optimal acetobacter activity. The temp down here generally givers around 65°F/18°C, and the optimal temp for acetobacter is above 77°F/25°C.

Therefore, I’m going to remove the aeration stones and just let these sit for a few months more on a seed mat. I’m not bothering to plug it into a temperature controller, since I don’t even think it will reach 77°F.

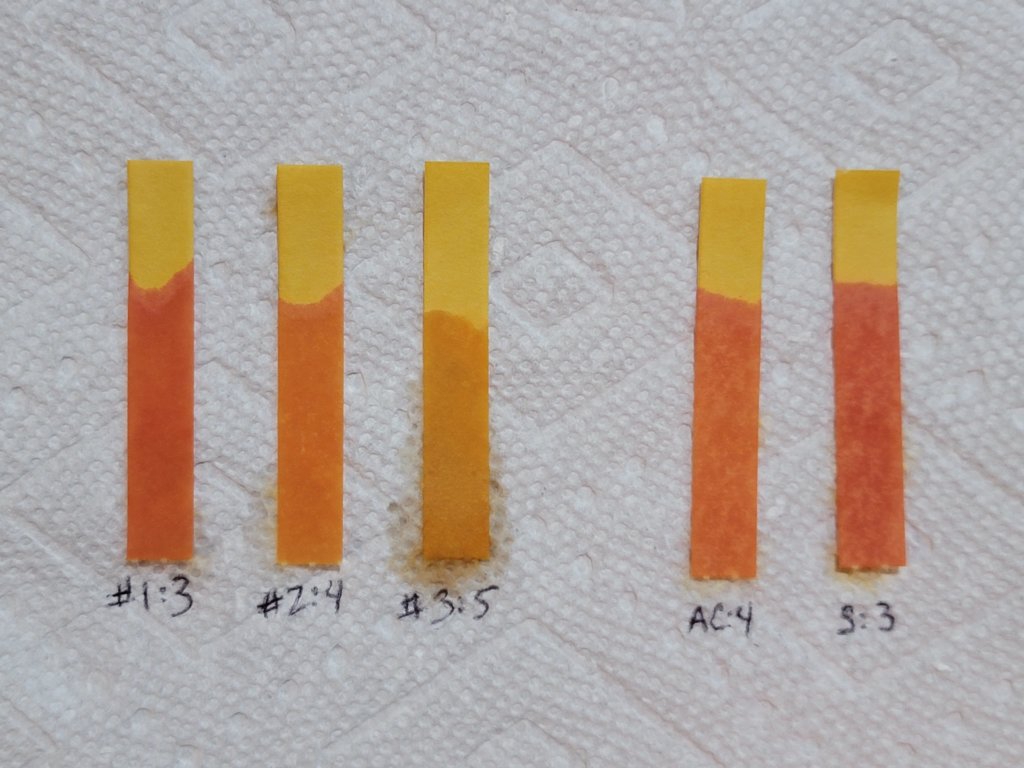

Day 100: 2021-11-14

The vinegars have now been going for a little over 3 months. Did I let them go too long? As you can see, the koji batch (3) is almost dried up, and the sugar fermented batch (2) is not far behind. Even the soju batch (1) is now just half full, after starting basically full.

I’m not sure why I’m so surprised that evaporation has occurred. Of course a liquid sitting open for months will evaporate. However, I was hoping that this would at least concentrate the vinegar to a pH that I’d be happy with. Well, here are the latest results:

I mean, batch #1 finally did get to where I wanted it. I’m pretty happy with that, especially considering it was the easiest method. Does this mean that you shouldn’t ferment your own alcohol first before turning it into vinegar? Absolutely not. I’d just recommend being more careful than I was about the strength of the alcohol you’re brewing.

I strained batch #1 gently through butter muslin in a fine mesh strainer. The result is an orange, cloudy liquid (which will probably settle given some time), and also roughly 3/4 of a cup of what basically looks and tastes like a very tart ketchup without any seasoning.

I’ve also strained batch #2 in the same manner, but the yeast sediment renders the solids pretty useless (not that there was much since I strained before adding the vinegar starter). I got roughly 250mL from that batch.

Batch #3 was put through just the fine mesh strainer and there weren’t really any solids to speak of.

Results

I managed to get 1 full 750mL bottle of tomato vinegar, 250mL of the yeast fermented stuff, and about 90mL of what I’ve dubbed “tomato balsamic”, plus a bonus jar of tangy tomato paste out of this experiment, so I’m calling this a success.

Tasting Notes

Unsurprisingly, it tastes like vinegar, but of course there is a strong backdrop of tomatoeyness that I think will have some great applications in savory cooking.

The really nice thing about this particular batch is that I did not alter the tomato juice, so it retained quite a bit of it’s fresh tomato flavor, including the sweetness and hint of umami.

I stole a small sample from batch #2 as it was straining and the taste is very… different. I’m not saying it’s bad, but it’s doing something strange to my tongue that might be due to the excess alcohol left over. It also tastes a bit muddy, less sweetness and more yeasty flavors. Perhaps if I had halted the fermentation earlier it would have turned out sweeter.

I did also taste the sludge that is batch #3, for science. I was left stunned by how sweet and tart it is, paired with an earthiness similar to #2 but more savory than muddy. The texture reminds me of balsamic vinegar, which I suppose makes sense given that’s in very simple terms how it’s made. I will actually attempt to strain this batch as well and put it into a tiny bottle to enjoy with some cheese!

Final Thoughts

I recently attended Fermentation 2021 and sat in on Kirsten Shockey’s session about homemade vinegar (after all, the Shockey’s did just publish a book called Homebrewed Vinegar this year, I should have picked up a copy before starting this). She mentioned that acidity is more important than pH* when brewing vinegar, something I was not aware of until that session. The gist* is that the mass of acetic acid is what is important, and the pH measurement can vary based on other compounds present, especially for complex vinegars like this, but measuring acidity is way less convenient than a pH strip or meter. All of this is mostly only important if I was going to use this vinegar for canning, which I’m not.

Something else to note is that acetic acid reacts with ethenol to create ethyl acetate, an ester that is highly volatile, meaning it evaporates at a higher rate than water. I believe this is why batch 2 and especially batch 3 evaporated at an accelerated rate, since they fermented longer than they should have and likely had plenty of excess ethanol. That and ethanol is also volatile…

All of this is to say, I’ll definitely do some additional research before trying this again. I think fermenting with yeast should work fine, just know that you’ll be changing the original flavor of the fruit, and that it’s probably best to stop the fermentation to carry some of the natural sugars over into the finished vinegar.

This is very interesting. I wonder if you’ve tried this again? Also, do you think this would work as well with vodka or another high-alcohol spirt?